Custom metal stamping services: Bending, punching, blanking, piercing, and deep drawing

Cost-effectiveness of our metal stamping

At Štancovani dijelovi, we strive to reduce production costs while maintaining quality and thus deliver high-quality products at competitive prices. We achieve this by optimizing our business processes, using materials efficiently, and performing secondary operations in-house.

Efficient use of materials allows us to reduce waste and material costs. Performing secondary operations in-house streamlines the manufacturing process and minimizes outsourcing expenses. The reduced production costs per unit offset the initial investment in tooling and lead to a fast return on investment for our customers.

Versatility in production

We provide custom metal stamping services to companies across many industries. Whether it’s the production of small, precise components for electronics or large, heavy-duty parts for the automotive industry, we can deliver high-quality solutions and meet the specific needs of each industry.

Industries we serve

- Military

- Automotive

- Construction

- Electronics

- Agriculture and more

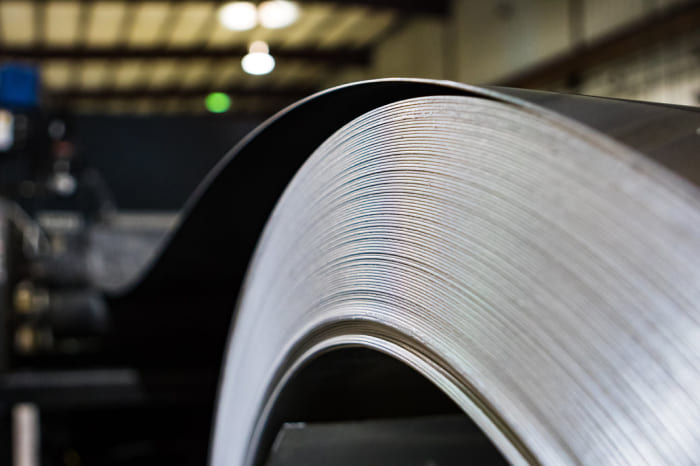

Material diversity

We work with a broad range of metals with thicknesses ranging from 0.5 mm to 10 mm. We carefully select the optimal metals based on strength, durability, corrosion resistance, and cost-effectiveness to ensure final products have the desired performance and a long lifespan.

Materials we use

- Carbon steel

- Copper

- Aluminum

- Brass and more

Precision and consistency

At Štancovani dijelovi, we strive to produce parts and components that are precise and consistent in terms of size, shape, and quality. We achieve this by using high-precision stamping dies and implementing strict quality control processes.

Using high-precision stamping dies ensures that each part produced has a consistent shape and size and meets the required specifications. Furthermore, our quality control processes and procedures ensure that all parts meet the required standards.